ABOUT

About Bi-Cast

About Bi-Cast

Proven ProcessesQuality • Integrity • Innovation • Service

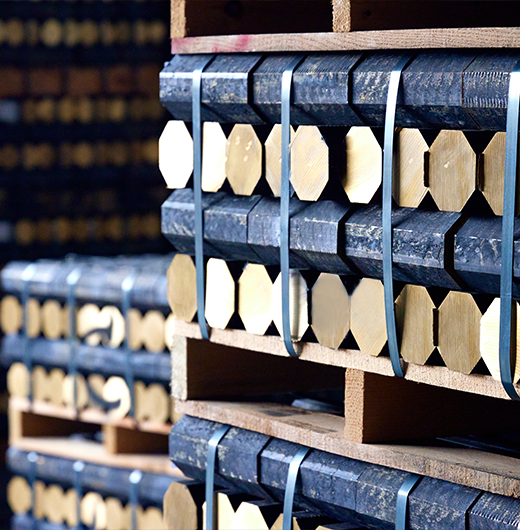

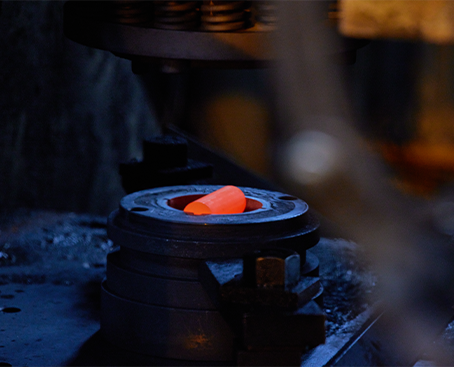

Founded in 1993 in Changhua, Taiwan, Bi-Cast Industrial specializes in free-cutting, forged, profiled, and lead-free brass rods, as well as copper alloy ingots. With over 30 years of experience, we uphold “Quality, Integrity, Innovation, and Service,” serving Taiwan and Southeast Asia. Equipped with German continuous casting machines and automated facilities, we operate a fully integrated production line to ensure stable quality, accurate delivery, and competitive pricing. Since 2020, our forging division—with monthly capacity of 200 tons—has supplied high-quality brass products for faucets, tools, plumbing components, and crafts to manufacturers worldwide.

- Advanced Casting & Automation

- Total Control, Stable Quality

- Integrated Production, Stable Quality

Key Milestones

Since 1993, Bi-Cast has embraced advanced technology and craftsmanship, growing into a trusted brass billet manufacturer with 30 years of milestones.

Established Bi-Cast De Brass Industrial Co., Ltd.,

Introduced German dual-tube casting machines.

2,000-ton extrusion machine

2,000-ton extrusion machine; brass rod production.

Second brass rod line added

Free-cutting & forged brass rods to international standards.

International Quality Certification

ISO 9001:2008 certified, pursuing quality excellence.

Low-lead & low-cadmium brass rods

RoHS-compliant eco brass rods; promoted green supply chain.

Phase II expansion completed

Miyazaki drawing machines introduced.

Gunmetal melting furnace added

Improved molten control; higher casting quality.

Bronze ingot series mass production

Expanded bronze ingot series; tailored to customer needs.

Forging division founded

Integrated production from raw material to forged products.